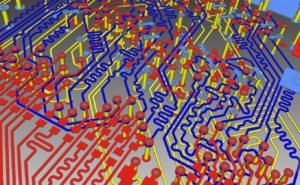

The creepage check within eCADSTAR’s PCB editor is a powerful tool and is so much more than a basic clearance check. The voltage difference can also be changed based on requirements for a voltage difference range. The flexibility and sophistication is down to the user control.

Creepage Check in Action

In this design I have maximized the input voltage to 600V at the power connector of our demo PCB Design, The first thing we need to do is define the voltage of the signals in the constraints browser. This is used in combination with the design rules to create the appropriate spacing to avoid creepage issues. In this demonstration, we will be focusing on the 600V signal.

Then in the Rule editor, there is now a new “voltage difference” tab Here is where we define the creepage rules. Here I have defined 3 clearance tables External_Coated, External_uncoated and Internal. These Rules are based on IPC standards which provides a formula for adequate clearances regarding creepage, you can use the formula or enter a defined value. This is therefore a clearance that varies with voltage difference but can also vary within a range of thresholds, making this a sophisticated solution for creepage rules. it is also a decision for the user if the voltage values are defined as RMS or Peak, as it is to define the voltage thresholds and values within the formulae.

Creepage Checker

From the report tab we can invoke the creepage checker. You can set a search distance around what is selected for a creepage check. eCADSTAR will check-in X Y & Z and even around the edges of the PCB

Once you have selected a signal, net, or the entire board a results dialogue will appear where you can filter by caution and fail results.

We can see from the results, creepage issues exist, creepage distance on the same external layers, for the 600V signal.

The error line is helpful as it is a guidance as to where we need to rectify the creepage failure, in this example we will take the traditional approach of inserting a slot in between the signals, Using eCADSTAR’s slot command. You can see that this slot is not long enough to rectify the problem and the error line now shows a different path signal to signal. We can easily increase the slot length from the properties tab.

We can now see those violations have been resolved, we can also check the creepage path through this slot from layer 1 to 4.

So, what are the Key Benefits of the Creepage checker?

- Powerful and advanced creepage design and check

- Design right and with advanced creepage design rules

- Reduce iterations and design re-work

- Powerful rules specified to voltage difference, beyond traditional clearance

- Clearance varies with voltage difference, as opposed to discrete values

- Creepage design consideration integrated within design rules

- Efficient and productive design environment

- Improve design review efficiency

- Creepage checks reduce overall design time and improve quality

- Design and verify to IEC 62368-1 from the outset and during design process

eCADSTAR – Built to Help You Deliver Results

- PCB DE64-bit computing

- Mouse and touch screen operation

- Powerful graphics, enabling users to design in a native 3D environment

- Advanced Collaborative design, allowing design activities to occur concurrently

- 2D and 3D environments

- Multi-core processor