PCB Assembly

Utilise cutting-edge PCB assembly services from Quadra Solutions, where precision meets innovation. Elevate your electronic devices to new heights and stand out in the competitive market with the highest quality bespoke solutions.

PCB Assembly Services

At Quadra Solutions, our team of seasoned experts specialises in the meticulous assembly of bespoke Printed Circuit Boards (PCBs). With an extensive 20-year track record in the industry, our assembly line consistently exceeds the exacting specifications of your designs. Offering both the quickest service available in the UK and the most cost-effective solutions tailored to your specific requirements, our team ensures unparalleled professionalism in meeting your PCB assembly needs.

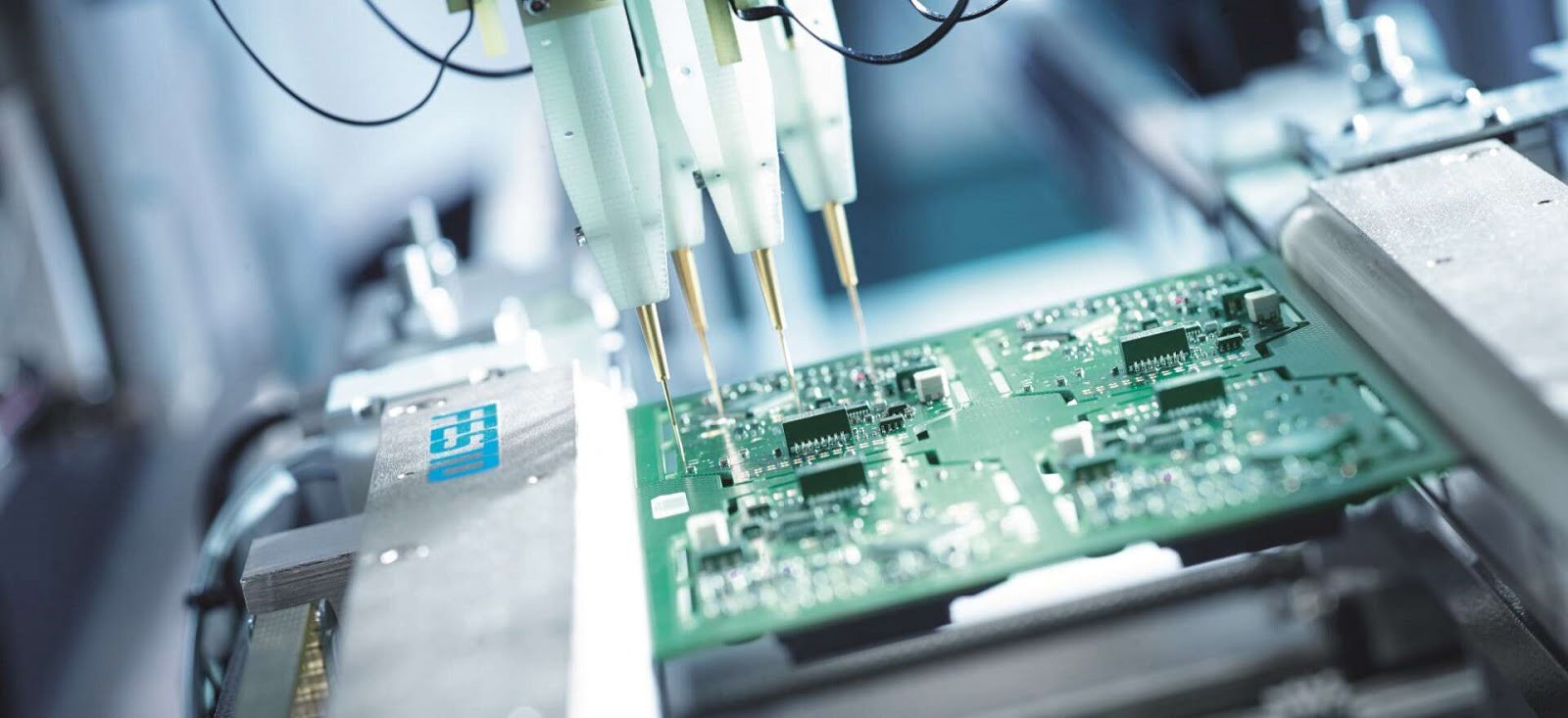

Our Printed Circuit Board Assembly Process

Uncover the intricacies and unparalleled precision of Quadra Solutions’ cutting-edge PCB Assembly Process, meticulously designed to elevate your electronic innovations. Our adept team of seasoned experts specialises in the artful creation of bespoke Printed Circuit Boards (PCBs), carefully tailored to meet and exceed your exact specifications. Immerse yourself in the flexibility of our dual delivery options – opt for quick delivery, guaranteeing a rapid turnaround at an additional cost, or choose the more affordable option, providing a cost-effective solution with a slightly extended waiting time. Our method of processing ensures your order is ready when you need it to be.

Experience a journey where each step reflects our commitment to delivering exceptional quality. From the initial design consultation to the final assembly, our meticulous attention ensures your PCBs are crafted to perfection.

Quadra Solutions takes pride in offering not just a service but an immersive experience, where every nuance is attended to with the utmost professionalism. Regardless of the chosen delivery option, rest assured that our process guarantees superior quality at every stage of PCB assembly.

Contact Us

Our PCB Assembly Service Capabilities

From Surface Mount to Mixed Technology Boards, Quadra Solutions excels in rapid prototyping, high-volume production, and efficient material procurement. Experience precision with our mechanical assembly and quality assurance. Discover the main capabilities of our team below.

- Surface Mount Assembly (SMT)

- Conventional PCB Assembly (Through Hole)

- DFM Check

- Flow Solder & Hand Soldered PCBs

- Mixed technology Printed Circuit Boards & double-sided SMT

- Automated prototype

- BOX Build – Mechanical assembly

- Full material procurement

- AOI PCB Inspection

- Dedicated Functional Test / Flying Probe

- ERP system to track component availability & lead times

"Tactiq have been using Quadra for twenty years. We have found the team at Quadra skillful and very responsive in meeting our PCB design needs. We recommend Quadra as our preferred supplier."Alan Johnson Tactiq

- Certified Quality Standards

Quality cannot be sacrificed when manufacturing your Printed Circuit Boards. That's why when you choose Quadra, you choose quality. We have helped assemble hundreds of boards and have over 20 years' experience in the industry!

- Save Time & Money

We are able to assist you in the process from the design stages right through to assembly and manufacture. Allowing us to look after your designs means you ensure you don’t have to do costly re-runs of any errors which may occur. We can assist in all elements from sourcing parts to manufacture and assembly. We have IPC CID+ designers on hand at all times and we offer a personalised service.

- Dedicated Account Manager

You will be assigned a dedicated account manager who will work closely with you throughout your manufacture and assembly process. They will project manage all aspects from procurement of parts to lead-times and costs.

- Automatic Quality Inspection

All assembled boards will pass through an AOI system to ensure there are no errors present. Having an inspection process allows us to get it right first time!

- Good Component Quality

The procurement of parts is left to the professional assemblers, their expertise and long-term cooperation with the suppliers help them to get the best component quality at the lowest price.

- Early Problem Detection

One painful experience you want to avoid is realizing a mistake when you have already spent too much on the PCB. An error that occurs during prototyping for the printed circuit board is better detected before the boards are produced. Ordering parts separately exposes you to that danger. Allow us to take this pressure out of your hands!

-

6,000+

Delegates trained

-

1,326+

Manufactured Prototype PCBS

-

27,151+

Purchase Orders Raised

-

6,212+

PCB Designs Completed

-

2,221+

PCB Designs Fabricated

-

15,000+

Support Cases Dealt with

- Phone +44(0)1254 301888

- Email hello@quadrasol.co.uk

Gold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.

PCB Assembly