Standard practices, Extraordinary results

Standard practices, Extraordinary results

Background

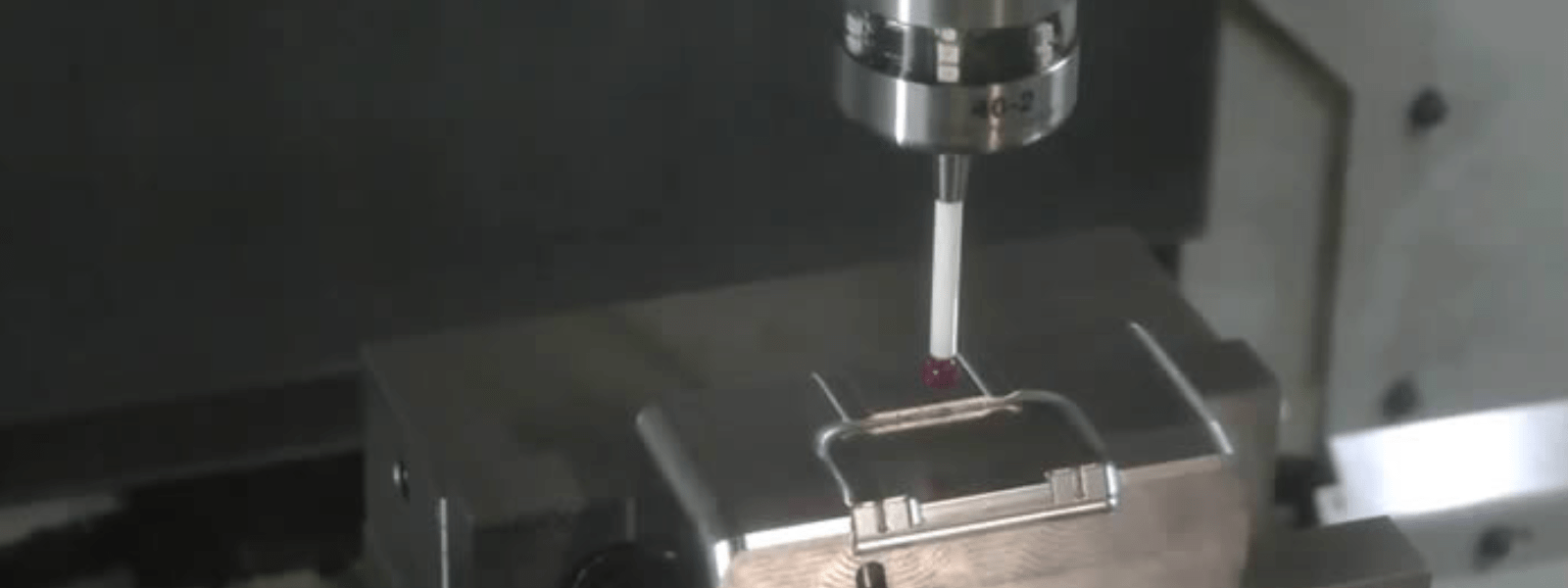

Kavia Tooling Limited is a Yorkshire based British firm who specialise in the design and manufacture of complex or simple precision injection mould tools and plastic components. Continued investment in new injection moulding machines and advanced 3D design technology ensures efficient production, and that components are produced to the required tolerance levels. Being a pioneering company, keen to develop advanced working processes and employ the most progressive technology, Kavia was the first company in the UK to trial and implement Autodesk Inventor Tooling 2009. Autodesk Inventor Tooling is a new suite of technology for the European market and is developed specifically for mould tool design and manufacture. This suite has the specific tools required to create split lines, ejection points, fill marks, validate mould designs and much more. Inventor Tooling uses Moldflow technology, the industry standard, to ensure that all designs are optimised and high levels of anaylsis can be conducted to check flow and time to fill, air pockets and quality.

Download Case Study“After evaluating the other options out there, to me, Inventor is still the most complete suite of technology and working with Quadra I feel that we are starting to really go places"Chris Cole, Managing Director

The Solution

The business relationship between Quadra Solutions and Kavia began in 2005 and it was this relationship that led Kavia to Inventor Tooling. Although not officially released in the UK market, because of the strong relationship between Quadra and Autodesk and liaising closely with them, Quadra managed to secure a test version of the software for Chris Cole, head of design at Kavia. Chris had been assessing the tooling solutions available on the market and had evaluated Vero, Unigraphics and SolidWorks. When Chris was shown Inventor Tooling and saw how easy and intuitive the user interface is, he was convinced this was the solution they were looking for.

The aim would be to not only design and implement individual components in a design and see how they work, but also to compile accurate bills of materials, eliminating any costs involved in over ordering materials on large Pipework schemes.

Chris explains, “We have been working with Quadra for a number of years now. We first got in contact when we were looking for technical support and someone to manage our subscriptions for us. I had been completing mould tool designs within Inventor and it could do it, but it was quite complicated and to teach someone else how to use my work flow would have been impossible.”

Results & Future

Through consultation and finding out more about the business Quadra were able to look at the challenges facing Kavia, specifically designing mould

tools in standard Inventor. Quadra suggested considering the powerful tools available Inventor Tooling. Steve Bedder from Autodesk and

Quadra’s technical engineers visited Kavia and demonstrate the wide range of efficient benefits that could be derived from a move to Inventor Tooling

and the additional support available through training and support. Chris says, “Inventor Tooling is the perfect solution at the perfect time for

us. It is easy to use and with a bit of training I think I can get my guys up to speed with it very quickly.”

Kavia are now driving forward and considering purchasing Product Design Suite. Their state-of-the-art mould making equipment, engineering technical and mould support, part design to part production and tooling project management put them in a strong position moving forward.

“Inventor Tooling is the perfect solution at the perfect time for us. It is easy to use and with a bit of training I think I can get my guys up to speed with it very quickly.”Chris Cole, Managing Director

More Case Studies

Your Partner for Design Success

Give us a call on +44(0)1254301888, or email us on hello@quadrasolutions.co.uk and let's talk!

Get In TouchGold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.