Engineering driven by passion, defined by results

Engineering driven by passion, defined by results

Engineering driven by passion, defined by results

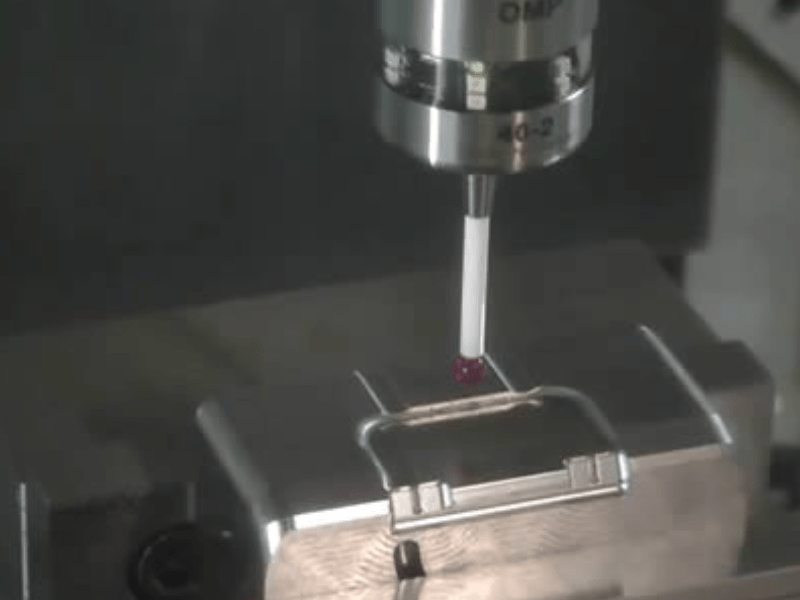

Allspeeds has a great many years of experience in manufacturing for the engineering industries. Today, the East Lancashire company makes specialist cutting equipment to help repair oil platforms and other large scale projects, such as providing under-watercutters, capable of slicing thought 190mm solid steel ropes in less than 120 seconds. The equipment they create is used by sub-sea technology companies, oil rigs and nuclear companies.

Most oil rigs in the Gulf of Mexico are situated in 6,000 feet of water and held to the sea bed by ropes as large as 1 62mm high tensile steel rope which are connected by suction anchors to the ocean floor. Allspeed create cutters which are able to slice though the ropes that anchor oil platforms to the

seabed. Allspeeds were given the challenge to design a cutter that would operate under these conditions, one of the largest they have ever created. Through this they developed the RCV1 90, a cutter capable of severing over 7 inch diameter steel rope; this design operates with 690 Bar (1 0,000 psi) cutting power and is designed to work down to a depth of 10,000 feet. The challenge came when Allpseeds were approached by a major offshore marine contractor at the end of December and were asked if they could make this cutter in 4 weeks. Mike Hollyhead, Managing Director says, “I advised that the usual lead time on this sort of project was 12 weeks and gave them my response that it was not possible.”

"Now that the design is done other variations on the design are very easy to duplicate without starting from scratch"Keith Elliot, Manufacturing Manager

Solution & Results

Allspeeds had recently purchased Autodesk Inventor from Quadra Solutions and the RCV1 90 was designed. The ease of design and the simplicity of the designers to pick up usages of Inventor meant that whereas previously the cutter, branded Webtool, would take 12 weeks to build instead was produced in just four.

This was the first major project for Allspeeds using Inventor.

Keith Elliot, Manufacturing Manager, said, “The ability to design the whole assembly on one system while still allowing two people to work on the design, made it easier to design.” With Quadra Solutions being an Autodesk Authorised Training Centre, Allspeeds invested in training and were pleased with how easy it was to utilise Inventor for novices and the success the software training created. “In the past we have over built and then cut out excessive material, Inventor allows us to build to the right size from scratch.

This in turn allowed the deployment of multiple resources during the build which enabled us to start manufacture before the design had been completed, reducing the design to manufacture time” said Keith Elliott. The reason for the tight deadline is that a typical platform can be losing 145,000 barrels of oil per day. By designing and manufacturing within a 4-week time frame (over a 60% time saving on the usual lead time on projects like this) Allspeeds have the potential to save oil producers over two million barrels of oil in lost revenue. Following on from its success with Inventor, Allspeeds are now planning on a new product enhanced range designed in the 3D technology, with the benefits of single bodied analysis, and the weight saving due to more accurate build and design processes. “Now that the design is done other variations on the design are very easy to duplicate without starting from scratch,” Keith Elliot advised.

The Future

Allspeeds have since widened their client base working with Nuclear power stations like Sellafield on a lifting tool, to support the Nuclear decommissioning and also supporting the aviation industry working with clients like Jet2 to create bespoke Hydraulic Jacks. Allspeeds have also created tools for the subsea, nuclear, oil and water industries, with many of the tools created, becoming the preferred industry standard. Their ability to work to a clients brief and design bespoke items that fit their customers needs, through the use of Inventor, has meant that they can stay responsive to their customers requirements and build a strong and loyal customer base.

“The ability to design the whole assembly on one system while still allowing two people to work on the design, made it easier to design.”Keith Elliot, Manufacturing Manager

More Case Studies

Your Partner for Design Success

Give us a call on +44(0)1254301888, or email us on hello@quadrasolutions.co.uk and let's talk!

Get In TouchGold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.