IPC, CID & CID+ Training Courses

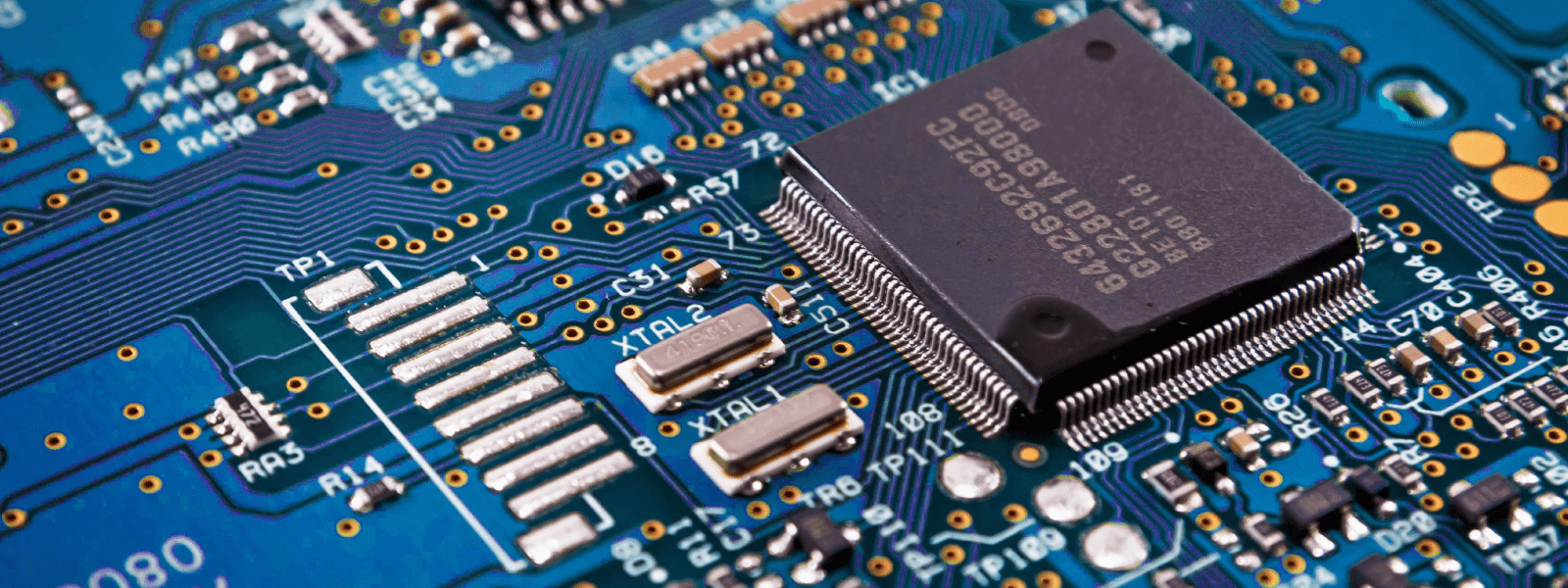

Quadra Solutions accelerates your PCB design career with the IPC Designer Certification. Our CID and CID+ programs offer top-notch professional development for industry-leading skill advancement.

IPC Certified Interconnect Designer Training

Looking to become a proficient PCB designer? Quadra Solutions’ IPC Training Courses are essential for anyone aspiring to enhance their skills in the Printed Circuit Board (PCB) design industry. These comprehensive courses cover fundamental aspects such as component placement, track routing, and delve into more advanced topics like PCB design principles, routing, and board stack-ups. All courses are conducted either at a learner’s location, a designated training centre, or through a hybrid arrangement of online and in-person sessions.

IPC CID Course

Boost your PCB design skills with Quadra Solutions’ IPC CID Course. This concise two-day program, available on-site or at a training centre, concludes with an exam, and successful candidates receive their certification in-person. Elevate your expertise in Certified Interconnect Design efficiently and effectively.

Become CID CertifiedBook Now

IPC CID & CID+ Training

"Undertaking training with Quadra has enabled us to understand the benefits of efficient and effective design, whilst helping cut costs"Cobham

IPC CID+ Course

This course specifically caters to existing PCB design professionals who have a number of years’ experience, and would benefit from the recognition of their skills and confirmation that their designs comply with accepted international standards.

Many delegates undertaking this course have extensive industry experience and look to this course to further develop and enhance their skills, while also ensuring the success of their designs to the current industry standards.

The training is suitable for:

- PCB assembly Professionals

- Engineering staff and managers with interest in design

- Sales

- Fabrication Managers

- Purchasing

- Research and Development

- Quality

- Test Engineer

Course Information

Course content covered in IPC CID

- PCB Design Considerations

- Thermal, Reliability and Testing Issues

- Physical Board Principles

- PCB Layout Principles

- Component Types

- Component and Assembly Issues

- PCB Surface Treatments

- Printed Board Characteristics

- PCB Design Documentation and Dimensioning

Course content covered in Advanced IPC CID+

- PCB Material Properties

- Assembly Test Implementation

- PCB Design Standards to Meet Fabrication and Assembly Goals

- Quality Life-cycle Tracking

- Panelization Strategy for Manufacturing Processes

- Electrical Clearance and Dielectric Spacing

- General Principles of Impedance Control for PCB design

- Component Comparison Between Area and Peripheral Arrays

- Component Mounting Strategies

- Material List Development

- Documentation to Facilitate Design to Fabrication Interface

- Phone +44(0)1254 301888

- Email hello@quadrasol.co.uk

Gold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.