Your Design Technology Partner

People . Knowledge . Innovation

Software solutions that make a difference

Reduce development costs and get to market faster

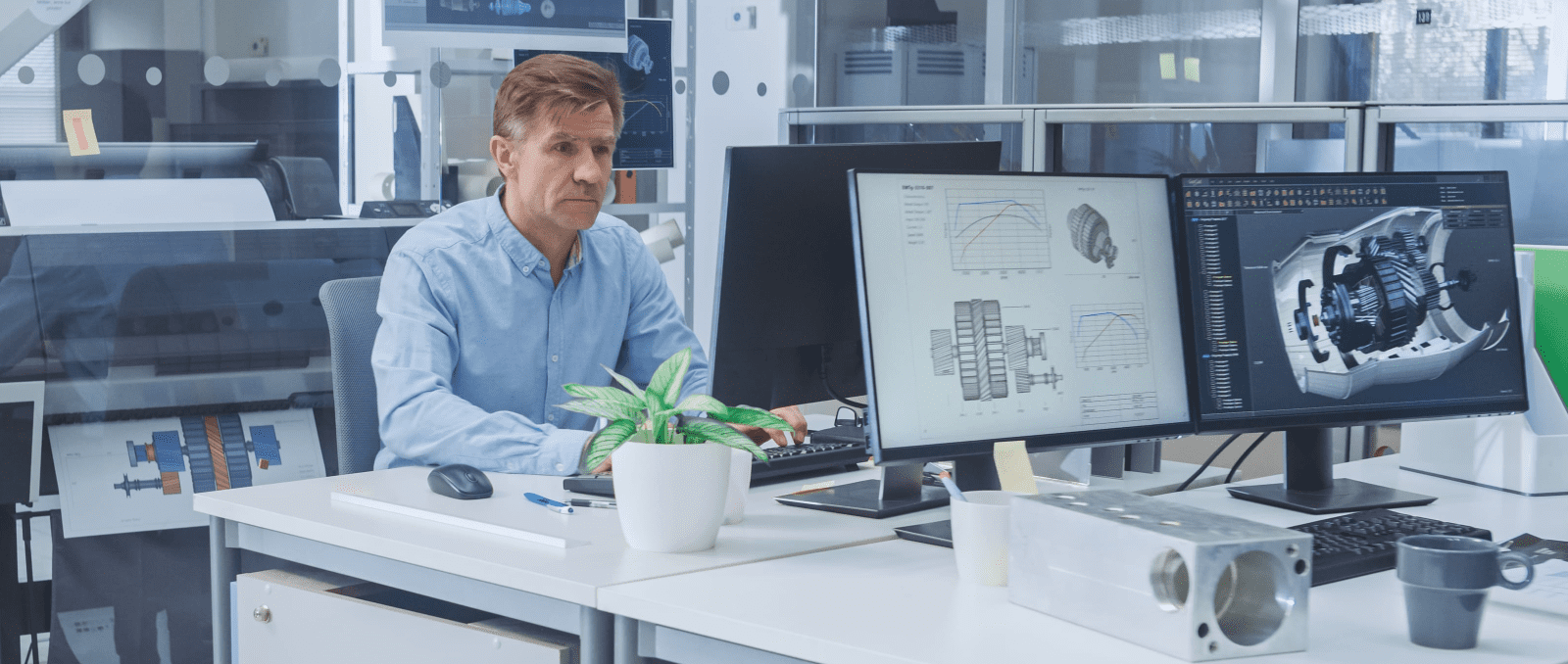

Turn your design ideas into reality with eCADSTAR

CAD Solutions for Mechanical, Construction & PCB Design

Your partner for design success

Quadra Solutions"The speed of technological enhancement is continuously increasing and it will be the ability to change and keep up with these developments that will be the standard by which success is measured."

Professional Development

and Training

Autodesk, eCADSTAR and IPC CID(+) Training Courses

"Undertaking training with Quadra has enabled us to understand the benefits of efficient and effective design, whilst helping cut costs"Cobham

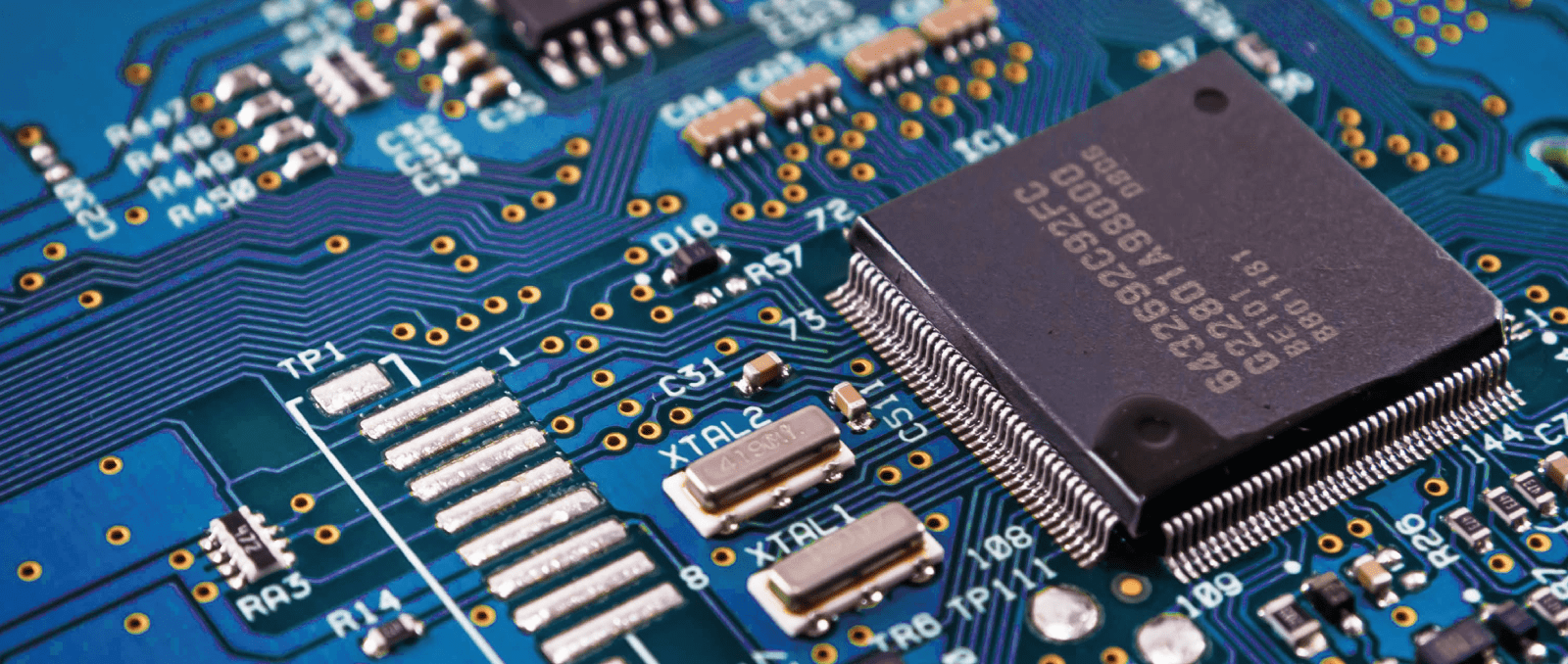

Our PCB Services

- PCB Design

You can rely on our highly experienced IPC CID+ accredited team of PCB Design Engineers to provide a full range of PCB Design Services that leave you free to focus on the design concept and product strategy

Find Out More - PCB Manufacture

We can assist with all your PCB manufacturing needs, we can provide a wide range of printed circuit boards

Find Out More - PCB Assembly

Many advanced skills are needed to achieve high-quality level PCBA, all requiring the right methods, machines and processes. Thats why you can trust Quadra to do this for you

Find Out More

Quadra In Numbers

Over 20 Years

-

6,000+

delegates trained

-

1,326+

Manufactured prototype PCBs

-

27,151+

purchase orders raised

-

6,212+

pcb designs completed

-

2,221+

pcb designs fabricated

-

15,000+

support cases dealt with

Technical Support Services

Guarantee design success with our technical support services

Our technical support services are designed with you in mind – we provide the help you need, when you need it. But we’re not just a support desk! What makes us different is the extra things we do to ensure that you are up to date with the very latest technology

Find Out More

"Since we made the move to Quadra we haven’t really looked back, they have the support, information and advice there when we need it."

You’ve got problems, we’ve got solutions

In the last few years, the manufacturing and engineering sectors have seen revolutionary changes. Quadra Solutions has been at the forefront of these technological advances, helping clients adapt and improve workflows

Find Out More

People.

Knowledge.

Innovation.

Gold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.