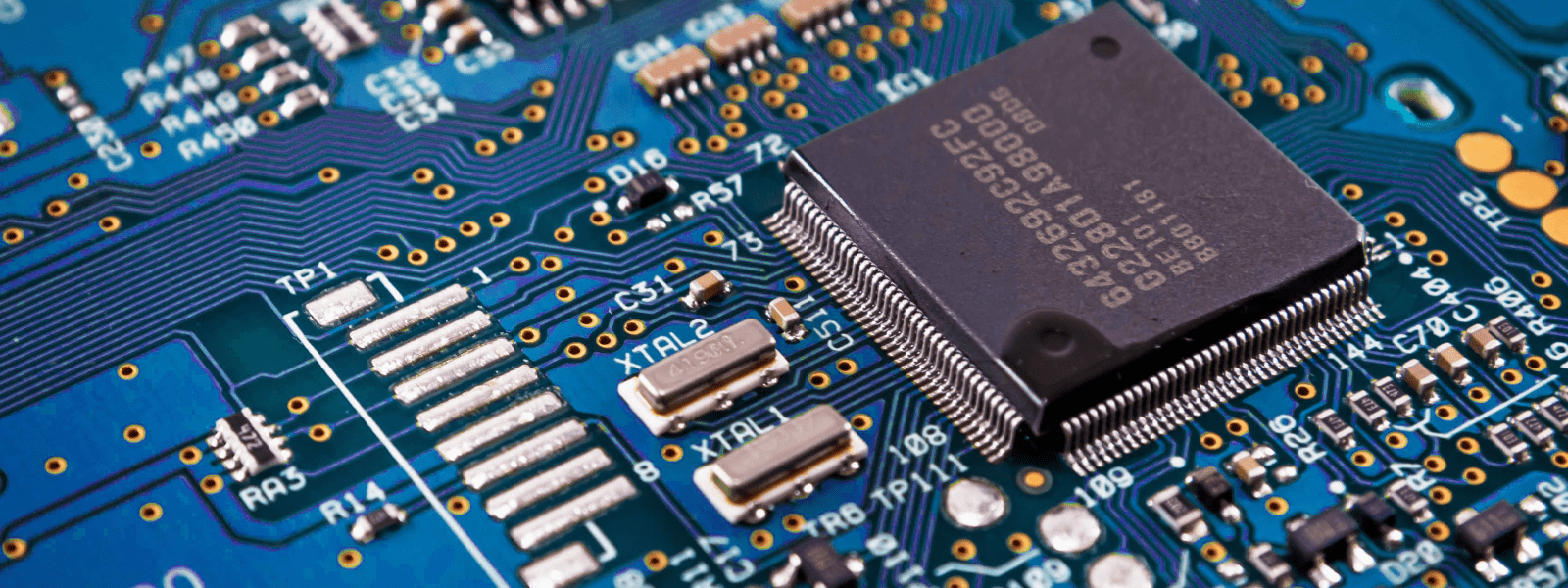

PCB Software Licences

Unlock the power of Zuken's industry-leading PCB software through Quadra Solutions for enhanced electronic design capabilities.

Zuken Printed Circuit Board Software

Acquire the best PCB design software with Quadra Solutions. We are committed to providing Zuken’s eCADSTAR and legacy CADSTAR software. Tailoring deals, packages, and affordable licences for businesses, organisations, and professionals, Quadra ensures access to state-of-the-art electronic design tools. Trust the Quadra team for comprehensive support and expert guidance, ensuring a seamless experience with Zuken’s PCB design solutions.

Download & Purchase PCB Software

Quadra Solutions partners with Zuken to ensure the highest quality and standards in PCB software. From budget-friendly software solutions to a comprehensive PCB software collection, discover the best printed circuit board software and packages below.

- Add on: eCADSTAR Power Integrity & EMI

For PCB Designers with more advanced requirements, top-class software starting from €219 / £193 per month

Product Details - Add on: eCADSTAR Signal Integrity

For PCB Designers with more advanced requirements, top-class software starting from €219 / £193 per month

Product Details - Auto-Router

Speed up your PCB design process with our powerful, cost-based, multipass, auto-routing environment

Product Details - CADSTAR

High-performance PCB Layout Software on your desktop

Product Details - eCADSTAR

Zuken is a global software company offering advanced design solutions for the creation and management of PCB designs, electrical and fluid systems and 3D cabinet and wire harness layouts.

Product Details - eCADSTAR 365

Zuken is a global software company offering advanced design solutions for the creation and management of PCB designs, electrical and fluid systems and 3D cabinet and wire harness layouts.

Product Details - eCADSTAR Advanced 3D

For PCB Designers with more advanced requirements, top-class software starting from €307 / £271 per month

Product Details - eCADSTAR Advanced HS

For PCB Designers with more advanced requirements, top-class software starting from €291 / £256 per month

Product Details - eCADSTAR Base+

Made for PCB designers involved in a lot of the design process, first-rate software starting from €237 / £209 per month

Product Details - eCADSTAR Engineer

For Electronic Engineers working with schematics, top-class software starting from €89 / £78 per month

Product Details - eCADSTAR Ultimate+

For PCB Designers with more advanced requirements, top-class software starting from €584 / £514 per month

Product Details - Gerber Import

A modest-sounding capability with nothing to be modest about. Importing Gerber data in eCADSTAR can get your PCBs to fabrication more quickly and reliably.

Product Details

Gold Autodesk Software Reseller for the mechanical and construction industries, sole UK reseller of Zuken’s PCB design software, eCADSTAR and Experienced PCB Design Bureau Specialists. We pride ourselves on our consultative approach to working with customers as their technology partner.