HSM or high-speed machining is an integrated CAM programming package for milling, turning and 2D cutting manufacturing methods, available as part of the Product Design & Manufacturing Collection.

HSM or high-speed machining is an integrated CAM programming package for milling, turning and 2D cutting manufacturing methods, available as part of the Product Design & Manufacturing Collection.

But what does HSM actually mean for manufacturing processes? And why are companies adopting it?

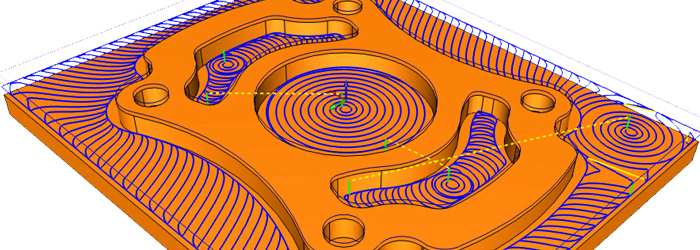

1. HSM can clear large quantities of material effectively

Adaptive Clearing helps to clear large quantities of material effectively during the tooling manufacturing process. It is unique in that it guarantees a maximum tool load at all stages of the machining cycle and makes it possible to cut deep and with the flank of the tool without risk of breakage.

Did you know Quadra Offer Inventor / Fusion CAM Training?

Find out more by contacting us

2. HSM provides users with an Integrated CAM software

One of the key benefits is that all CAD/CAM data is stored within the part file, meaning that all the data is self-contained within the model. The benefit of this being that if the part requires adaptation and alteration, the process of updating the CAD/CAM data is simple.

With all design data being stored in the same place and without having to move from one application to another, efficiencies can be derived. It can, however, also help provide a data trail for anyone working with Vault to manage data.

3 . Reducing ‘chatter’ through HSM can improve accuracy and reduce weight

HSM originally grew out of CNC techniques developed by aerospace manufacturing companies, with the aim of avoiding what’s known as “chatter” (machine vibration that can become noisy and/or violent). Chatter can lead to poor surface finish and poor tool life/longevity. HSM not only helps reduce chatter but as a result can mean that tool life is extended.

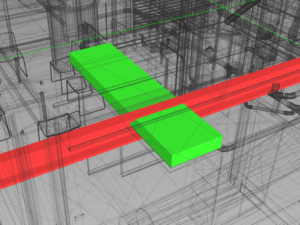

4 . Tool collision and clash information

InventorHSM and HSMworks allow you to include the tool holder as part of your calculations. This ensures that your paths are collision-free from not just the tool but also the tool holder. HSM also gives you the flexibility to match the best tool lengths to your part helping improve surface finishes.

5. Use of AnyCAD

With AnyCAD you can import data from other systems whilst maintaining associativity with the original model. Save time tracking down edits and engineering changes to help streamline the workflow. This enables you to stay on top of your data management and automatic access to the latest engineering changes.

More about Quadra Solutions

Quadra Solutions Ltd specialise in design and data management software solutions for the manufacturing, construction, engineering and PCB design industries. Quadra is a Gold Autodesk Partner, an accredited training centre and specialists in PCB design. Inventor, Revit, AutoCAD,Collections and Vault software help our customers to design, visualise, innovate and implement solutions that grow and develop their business.

Our software solutions, consultancy, training and technical support are some of the best in the industry. With a wealth of experience and knowledge, Quadra specialises in helping businesses adopt efficient and effective design workflows. We help them innovate and embed data management solutions. We pride ourselves on our consultative approach to working with customers as their technology partner. For more information about Quadra please contact us.

Email Us 01254 3018888

For more information please contact us today!